Description

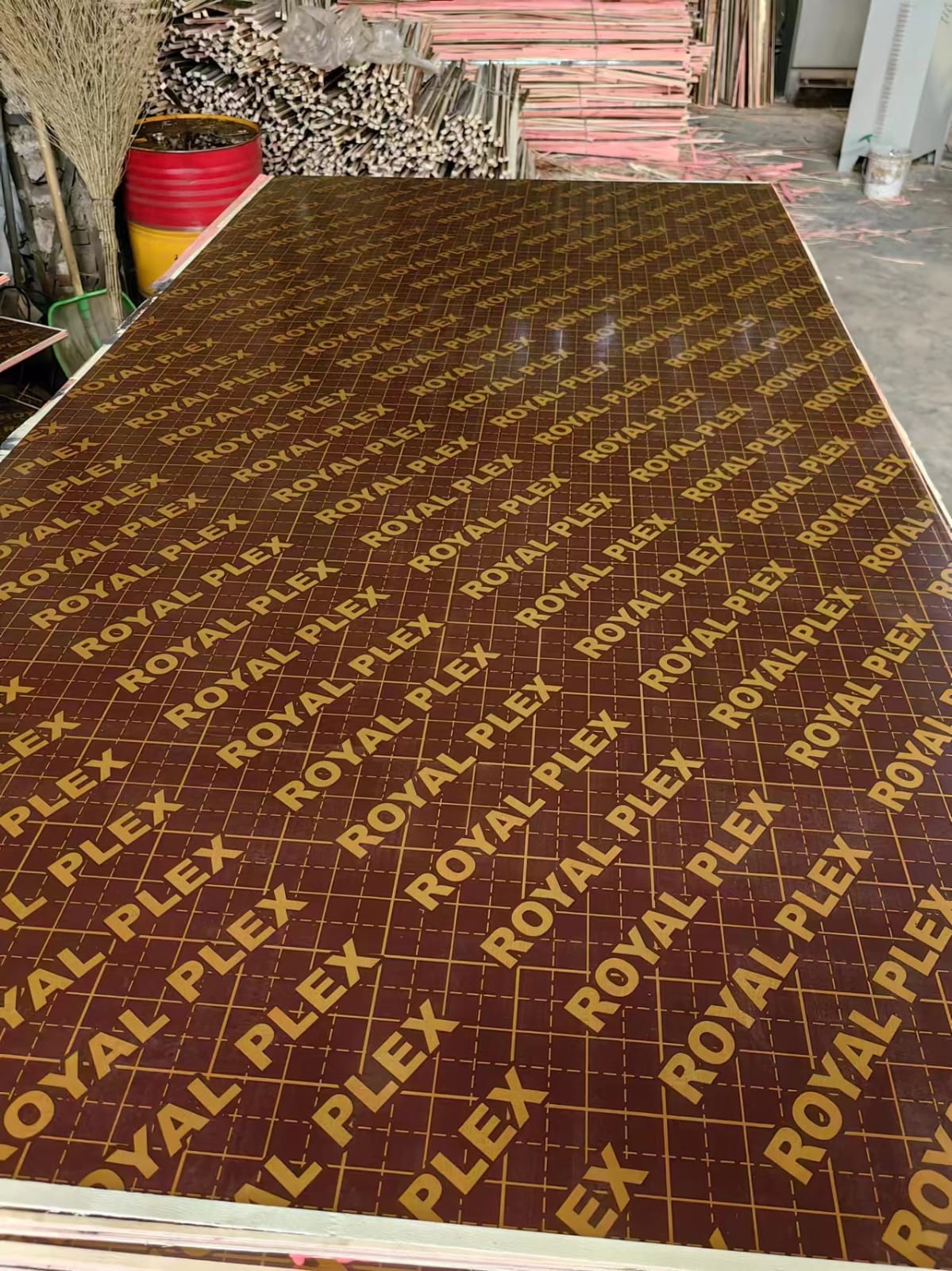

Hotpress Plywood – High-Density, Durable, and Moisture-Resistant | UAE

Hotpress Plywood is a versatile and durable wood product made by compressing multiple layers of veneer under high temperature and pressure. This process ensures a dense, uniform, and stable panel, which is less prone to warping and deformation compared to ordinary plywood. The hot pressing technique also makes the plywood more moisture-resistant, making it suitable for interior and semi-exterior applications.

Widely used in furniture manufacturing, interior paneling, and formwork, Hotpress Plywood delivers consistent performance and a smooth surface finish. Its high-density core provides robust structural support, while the uniform glue distribution ensures lasting bonding between the veneer layers.

Key Features:

- ✅ High-Density Structure: Ensures durability and resistance to warping

- ✅ Moisture-Resistant: Suitable for indoor and semi-exterior applications

- ✅ Smooth Surface: Ideal for laminating, painting, and veneering

- ✅ Strength and Stability: Withstands heavy loads and impacts

- ✅ Precision Manufacturing: Maintains uniform thickness and density

- ✅ Heat and Pressure Treated: Enhanced bonding between veneer layers

- ✅ Versatile Applications: Suitable for furniture, flooring, and interior paneling

- ✅ Standard Sizes: Available in 4×8 feet sheets with thicknesses from 6mm to 25mm

Applications:

- Furniture making and modular interiors

- Wall and ceiling paneling

- Kitchen cabinets and wardrobes

- Formwork for concrete construction

- Doors and partition walls

- Industrial packaging and crates